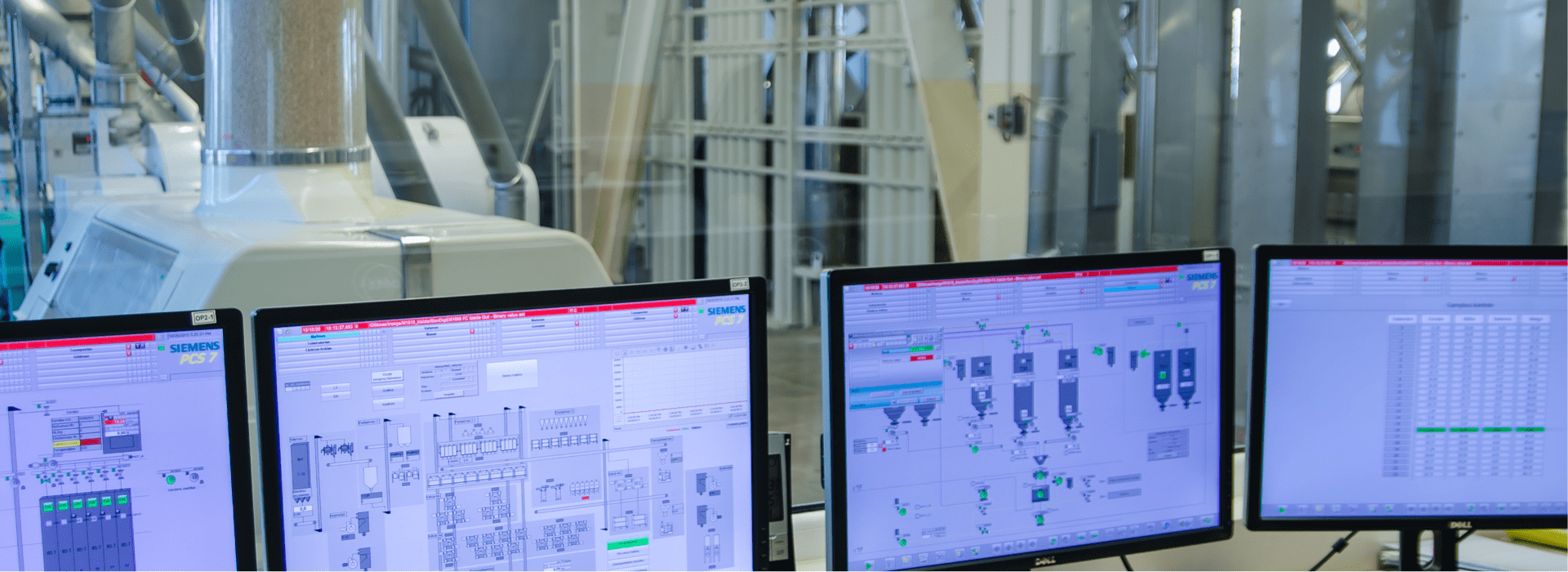

Follow & control production automation processes.

Unique, on-demand reports for remote viewing of production parameters and processes. Tracking helps reduce troubleshooting time. This speeds up the identification of causes, which reduces downtime, costs and increases efficiency.